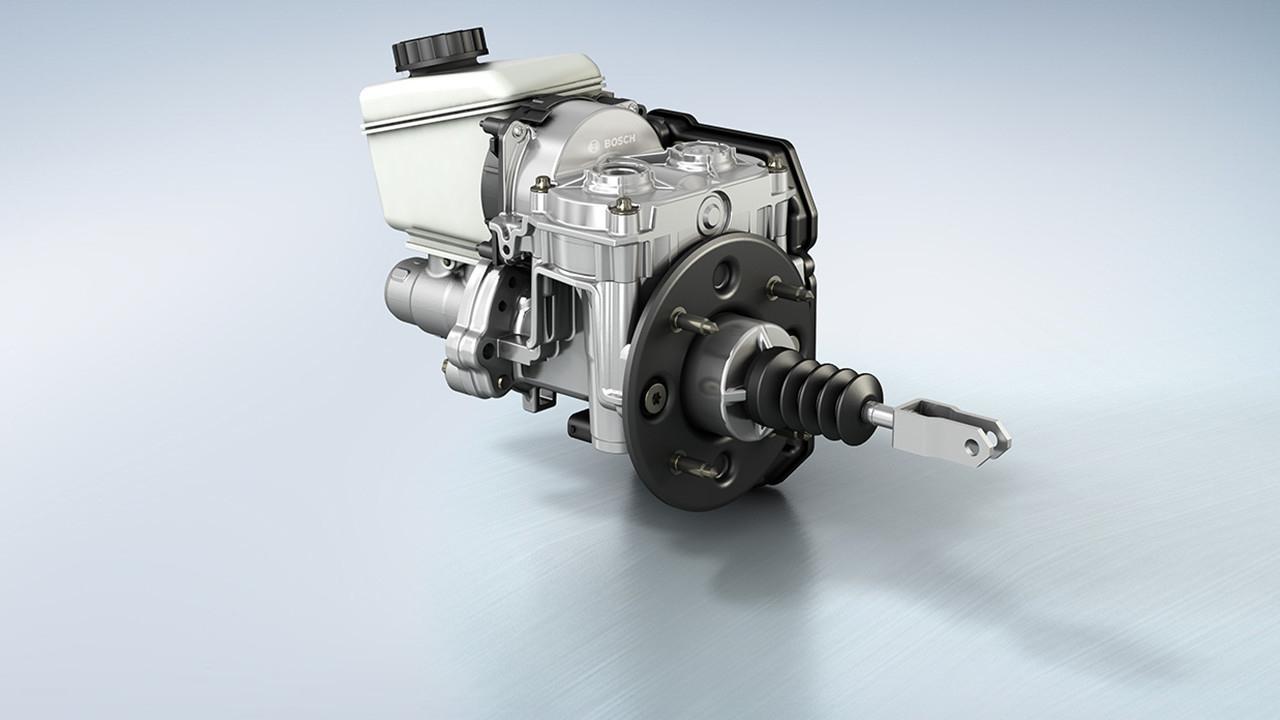

Without any doubts, brakes were the first and the most important one of all vehicle safety components. Already back in the 1920’s, automotive brakes hardly even coped with the engine performance and the weight of the vehicles of the time. The pneumatic servo brake presented by Bosch in 1927 significantly increased the road safety. Thanks to this invention, the braking distance of contemporary commercial vehicles was reduced by one third. One year later, Bosch presented the brake support, a compact brake assistance system for passenger cars. In 1936, even the basis for modern anti-lock braking systems was laid by Bosch engineers when Bosch filed a patent for a "mechanism to prevent locking of the wheels of a motor vehicle". But only in 1978, the powerful digital technology allowed the series production of an ABS (anti-lock braking system). By now, Bosch developments such as the ABS, the traction control system TCS launched in 1986, which was actually based on the ABS, and the electronic stability program ESP® launched in 1995 have turned into the most important components for safe braking.

Innovative Bosch developments for all brake components

For 90 years, Bosch engineers set new standards making cars safer by means of technical innovations, inventions and patents for brake systems. By now, anti-lock braking systems have become a standard in automotive engineering. The electronic stability

program ESP® is a legal requirement in several countries. Besides these electronic systems, Bosch developments have also improved the safe performance of all other braking components over and over again. In 1983, for example, high-carbon-cast brake

discs have significantly improved the braking performance of powerful vehicles.

Between 2001 and 2012, several innovations also have had an impact on the development of brake calipers. In 2016, Bosch presented the innovative high-performance

brake fluids ENV6 and ENV4 ensuring quick reaction and reliable performance of modern brake systems.

It’s all about the mixture: new friction formulations for brake pads

By means of innovative production techniques and new material blends, Bosch has managed to make progress in terms of brake pads over and over again. After all, they are to transmit the brake force in a reliable manner thus safely braking the vehicle. With regard to brake-pad development, road traffic regulations differing a lot from one country to another need to be considered as well as speed limits and environmental regulations. Bosch thus produces a lot of different brake pads to meet specific regional requirements which usually exceed the legal requirements by far. In 2010, for example, the US states Washington and California issued laws aiming on reducing the amount of copper used in brake pads. As a consequence, Bosch engineers developed a copper-free brake-pad mixture which was the first copper-free brake pad on the market eight years before the entry into force of the laws. The patent application was first filed in 2014. Even on the EU market, Bosch already offers copper-free brake pads –although they are not yet legally required.

Mónika Hack

+36 70 510 5516

The Automotive Aftermarket division (AA) provides the aftermarket and repair shops worldwide with a complete range of diagnostic and repair shop equipment and a wide range of spare parts –from new and exchange parts to repair solutions –for passenger cars and commercial vehicles. Its product portfolio includes products made as Bosch original equipment, as well as aftermarket products and services developed and manufactured in-house. About 18,000 associates in 150 countries, as well as a global logistics network, ensure that some 650,000 different spare parts reach customers quickly and on time. In its “Automotive Service Solutions” operations, AA supplies testing and repair-shop technology, diagnostic software, service training, and information services. In addition, the division is responsible for the “Bosch Service” repair-shop franchise, one of the world’s largest independent chains of repair-shops, with some 17,000 workshops. In addition, AA is responsible for more than 1,000 “AutoCrew” partners. The Bosch Group is a leading global supplier of technology and services. It employs roughly 390,000 associates worldwide (as of December 31, 2016). The company generated sales of 73.1 billion euros in 2016. Its operations are divided into four business sectors: Mobility Solutions, Industrial Technology, Consumer Goods, and Energy and Building Technology. As a leading IoT company, Bosch offers innovative solutions for smart homes, smart cities, connected mobility, and connected manufacturing. It uses its expertise in sensor technology, software, and services, as well as its own IoT cloud, to offer its customers connected, cross-domain solutions from a single source. The Bosch Group’s strategic objective is to deliver innovations for a connected life. Bosch improves quality of life worldwide with products and services that are innovative and spark enthusiasm. In short, Bosch creates technology that is “Invented for life.” The Bosch Group comprises Robert Bosch GmbH and its roughly 440 subsidiaries and regional companies in some 60 countries. Including sales and service partners, Bosch’s global manufacturing and sales network covers nearly every country in the world. The basis for the company’s future growth is its innovative strength. At 120 locations across the globe, Bosch employs some 59,000 associates in research and development. Additional information is available online at www.bosch.hu

The Automotive Aftermarket division (AA) provides the aftermarket and repair shops worldwide with a complete range of diagnostic and repair shop equipment and a wide range of spare parts –from new and exchange parts to repair solutions –for passenger cars and commercial vehicles. Its product portfolio includes products made as Bosch original equipment, as well as aftermarket products and services developed and manufactured in-house. About 18,000 associates in 150 countries, as well as a global logistics network, ensure that some 650,000 different spare parts reach customers quickly and on time. In its “Automotive Service Solutions” operations, AA supplies testing and repair-shop technology, diagnostic software, service training, and information services. In addition, the division is responsible for the “Bosch Service” repair-shop franchise, one of the world’s largest independent chains of repair-shops, with some 17,000 workshops. In addition, AA is responsible for more than 1,000 “AutoCrew” partners.

The Bosch Group is a leading global supplier of technology and services. It employs roughly 390,000 associates worldwide (as of December 31, 2016). The company generated sales of 73.1 billion euros in 2016. Its operations are divided into four business sectors: Mobility Solutions, Industrial Technology, Consumer Goods, and Energy and Building Technology. As a leading IoT company, Bosch offers innovative solutions for smart homes, smart cities, connected mobility, and connected manufacturing. It uses its expertise in sensor technology, software, and services, as well as its own IoT cloud, to offer its customers connected, cross-domain solutions from a single source. The Bosch Group’s strategic objective is to deliver innovations for a connected life. Bosch improves quality of life worldwide with products and services that are innovative and spark enthusiasm. In short, Bosch creates technology that is “Invented for life.” The Bosch Group comprises Robert Bosch GmbH and its roughly 440 subsidiaries and regional companies in some 60 countries. Including sales and service partners, Bosch’s global manufacturing and sales network covers nearly every country in the world. The basis for the company’s future growth is its innovative strength. At 120 locations across the globe, Bosch employs some 59,000 associates in research and development.

Additional information is available online at www.bosch.hu