Abstatt – In order to prevent common accidents during construction machinery operation, such as collisions with people or obstacles, drivers need to have a constant overview of the entire area surrounding their vehicle, which often involves considerable mental stress and physical strain.

Electronic driver assistance systems also make construction sites safer, while making the work of construction operators easier. These techniques are the first stage of automated construction. "Bosch has therefore developed a modular concept of on-demand systems and sensors for comprehensive assistant functions specifically for construction machinery. In addition, together with Bosch Rexroth, we also offer a control unit that forms the heart of the automated machine," explains Stefan Schenk, off-highway product area specialist at Robert Bosch GmbH.

Flexible sensor concept for construction assistance systems

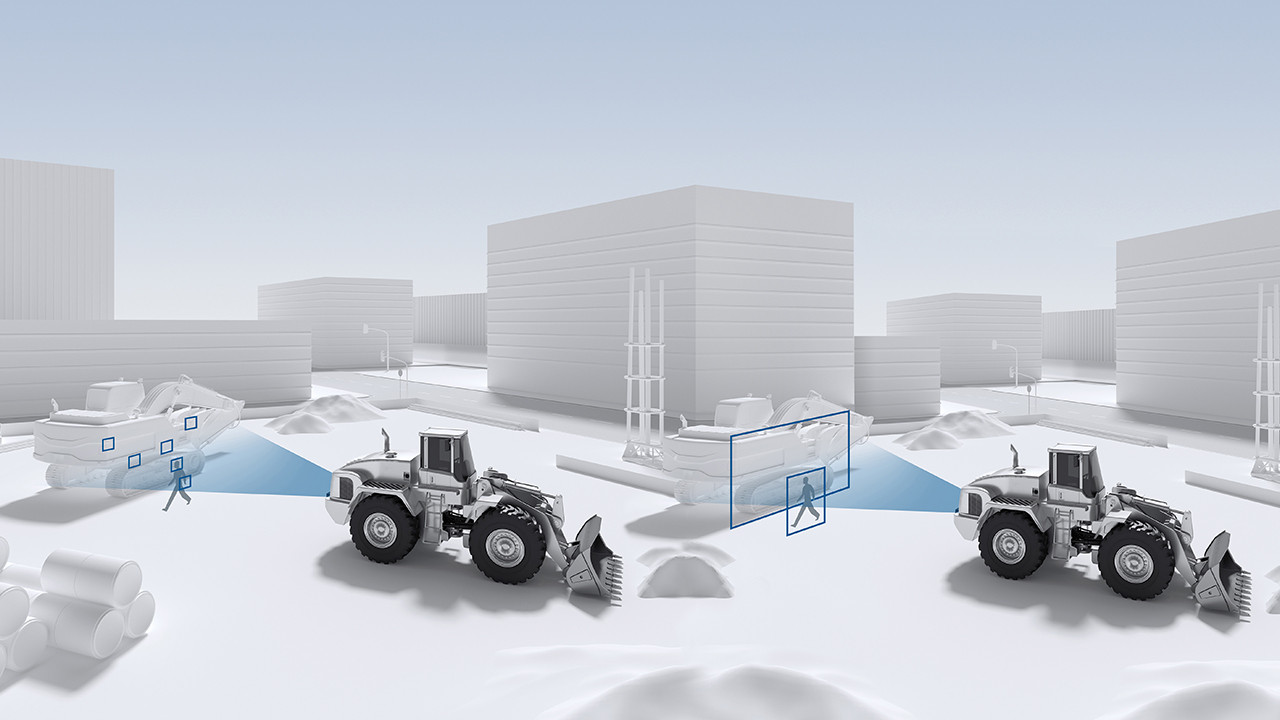

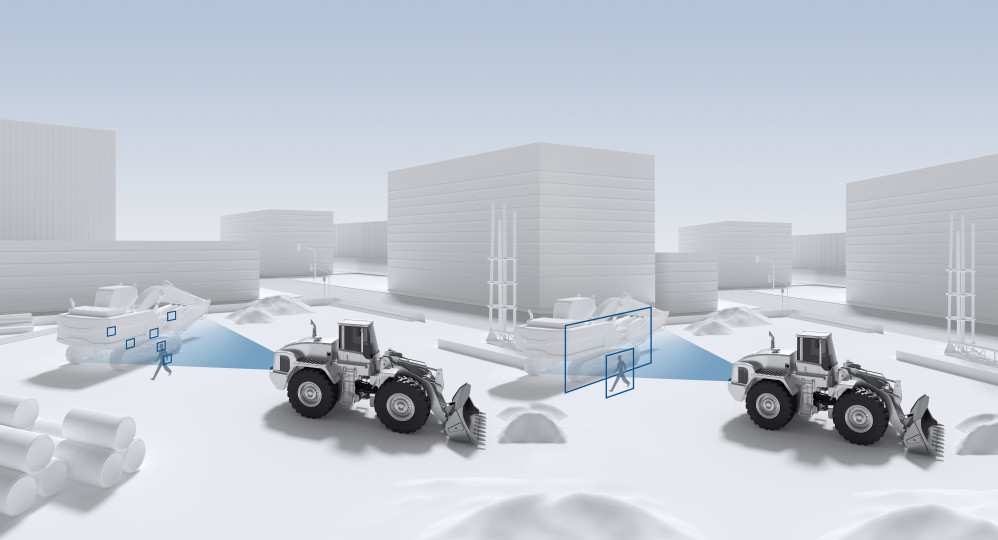

To make the vision of an automated construction site a reality, Bosch is already offering various assistance functions for construction vehicles today. They relieve the operator and make construction safer. Individual functions – such as load sensing in excavator buckets and a collision warning for safety in front of and behind the machine – can directly contribute to supporting the work. If these assistance systems detect people or objects in the danger zone, they warn the driver with a visual and/or audible warning and display the relevant objects on the screen. This gives the driver a clear view of the areas around the machine that are difficult to see.

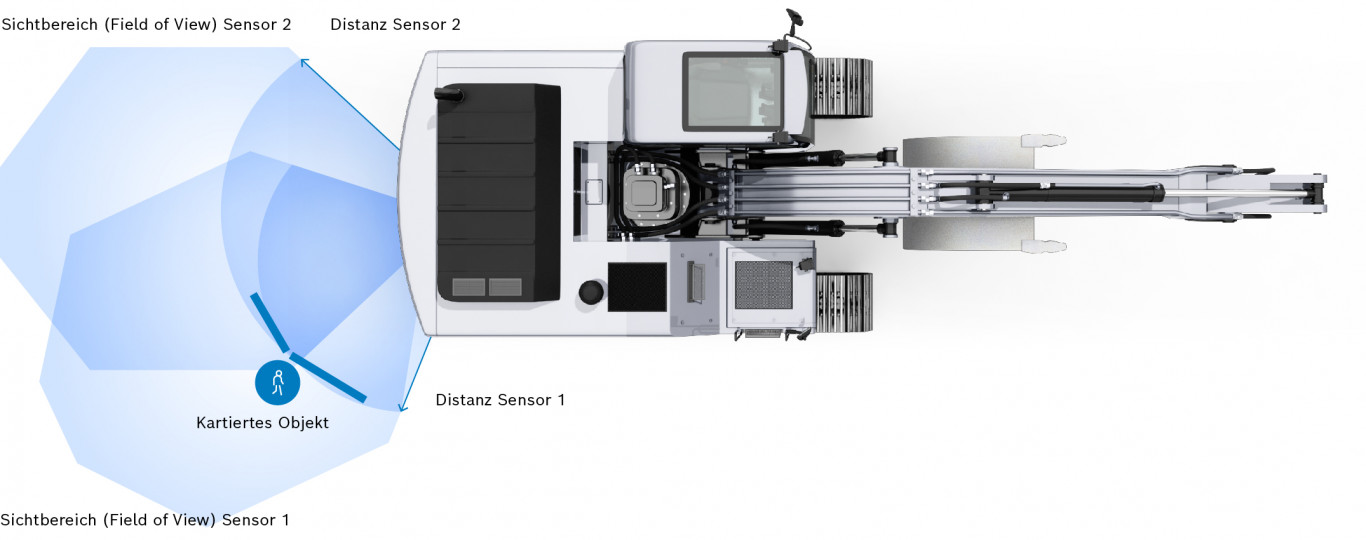

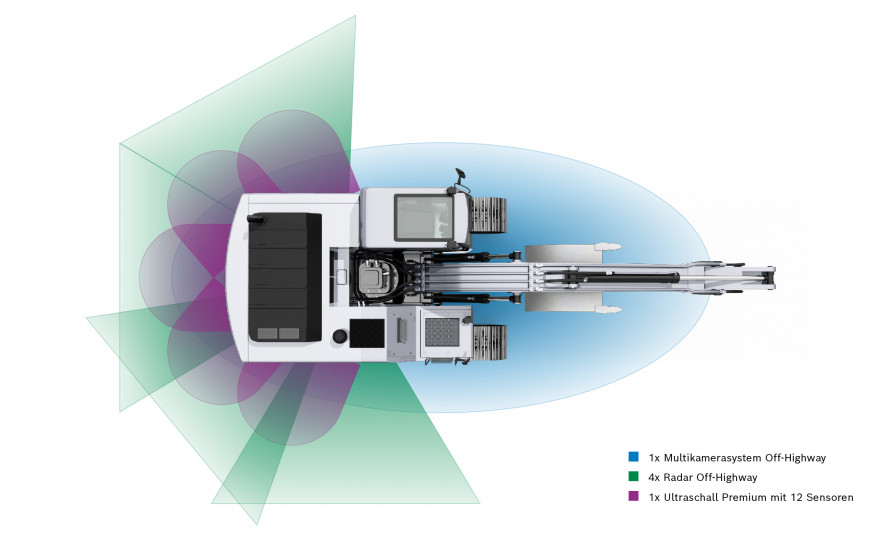

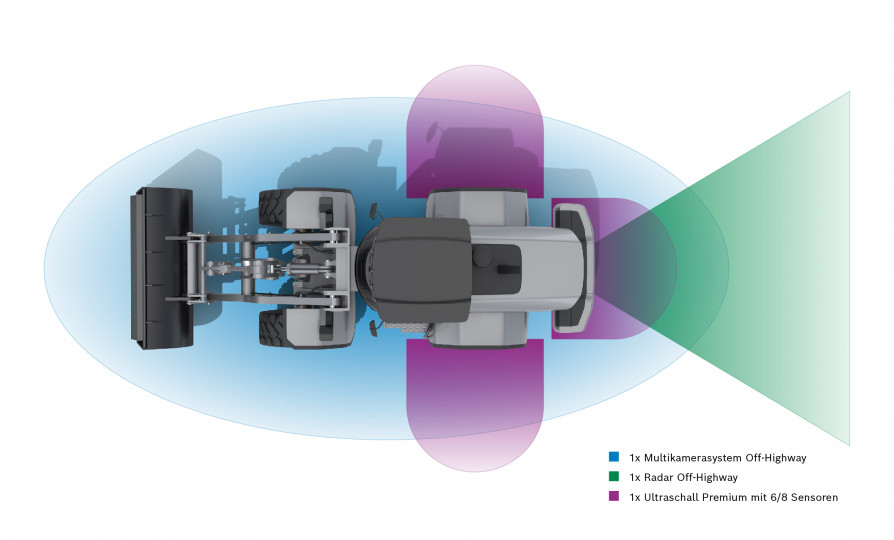

The sensor concept consists of different ultrasonic and radar solutions, as well as a multi-camera system. This allows flexibility and the possibility to tailor the protection to the specific application and assistance functions. To this end, Bosch intends to exploit the know-how and proven core technologies available in the automotive industry and further develop them for off-highway applications. The systems can thus combine a high level of functional safety with exceptional robustness, even under the toughest of operating conditions.

Concept of manufacturer-specific assistance functions

For simple processing of optical sensor information, Bosch has developed the Off-Highway Vision unit, which displays the video stream of the multi-camera system. This is complemented by a kind of overlay that visually highlights objects detected by radar and ultrasonic sensors in their detection area. The electronic fusion of sensor data optimally combines the advantages of different sensors operating on different principles to increase the performance of the assistance system.

This provides construction machinery manufacturers with a validated and functional basic modular system that allows them to design and develop their own assistance systems on demand, using the "plug and play" principle. Possible functions include, for example, blind spot monitoring, object recognition and maneuvering assistance.

Automation in the construction industry

The currently available assistant functions are the first step towards the future use of fully automated and connected machines in the construction industry. Together, Bosch and Bosch Rexroth are supporting this process with the Off-Highway Robotics Controller (ORC), a complete system that can be adapted, tested and verified for the specific application. The automation software and hardware from Bosch can be seamlessly integrated into Bosch's digital ecosystem (BODAS), which supports digital transformation, thereby increasing productivity and efficiency. " With the systems from Bosch, the vision of the automated construction site of tomorrow is already within reach today," Schenk stressed.

CU.BE opens – A glimpse into the factory of the future, coming soon to our doorstep

In 2023, CU.BE, the unique, innovative experience center of Bosch Rexroth Kft., will open its doors in the Bosch Budapest Engineering Center of Bosch Hungary. CU.BE will be a place for Industry 4.0 awareness-raising and knowledge transfer, where visitors can learn about the benefits of a connected, automated and sustainable industrial ecosystem through practical examples. At CU.BE, visitors can learn about industrial digitalization through state-of-the-art tools such as augmented reality glasses.

Digitalization: haptic collision avoidance

https://www.youtube.com/watch?v=yOFWV5c6fQY

Zita Hella Varga

Phone: +36 70 667-6374

About Bosch Engineering GmbH

Bosch Engineering GmbH is a wholly owned subsidiary of Robert Bosch GmbH and is head-quartered in Abstatt, Germany. As a systems development partner to the automotive industry since 1999, the company with its more than 3,000 associates offers development services for powertrains, safety and convenience systems, and electrical and electronic systems – from the original concept to series production. Specialized in electronics and software, it draws on Bosch’s proven large-scale series production technology to develop tailored solutions for a wide variety of applications in passenger cars, commercial vehicles, off-highway and recreational vehicles, and in rail applications, ships, and industry. Bosch Engineering GmbH also coordinates all the Bosch Group’s motorsports activities.

Additional information can be accessed at www.bosch-engineering.com.

Mobility Solutions

Mobility Solutions is the largest Bosch Group business sector. It generated sales of 45.3 billion euros in 2021, and thus contributed 58 percent of total sales from operations. This makes the Bosch Group one of the leading automotive suppliers. The Mobility Solutions business sector pursues a vision of mobility that is safe, sustainable, and exciting, and combines the group’s expertise in the domains of personalization, automation, electrification, and connectivity. For its customers, the outcome is integrated mobility solutions. The business sector’s main areas of activity are injection technology and powertrain peripherals for internal-combustion engines, diverse solutions for powertrain electrification, vehicle safety systems, driver-assistance and automated functions, technology for user-friendly infotainment as well as vehicle-to-vehicle and vehicle-to-infrastructure communication, repair-shop concepts, and technology and services for the automotive aftermarket. Bosch is synonymous with important automotive innovations, such as electronic engine management, the ESP anti-skid system, and common-rail diesel technology.

The Bosch Group is a leading global supplier of technology and services. It employs roughly 402,600 associates worldwide (as of December 31, 2021). The company generated sales of 78.7 billion euros in 2021. Its operations are divided into four business sectors: Mobility Solutions, Industrial Technology, Consumer Goods, and Energy and Building Technology. As a leading IoT provider, Bosch offers innovative solutions for smart homes, Industry 4.0, and connected mobility. Bosch is pursuing a vision of mobility that is sustainable, safe, and exciting. It uses its expertise in sensor technology, software, and services, as well as its own IoT cloud, to offer its customers connected, cross-domain solutions from a single source. The Bosch Group’s strategic objective is to facilitate connected living with products and solutions that either contain artificial intelligence (AI) or have been developed or manufactured with its help. Bosch improves quality of life worldwide with products and services that are innovative and spark enthusiasm. In short, Bosch creates technology that is “Invented for life.” The Bosch Group comprises Robert Bosch GmbH and its roughly 440 subsidiary and regional companies in some 60 countries. Including sales and service partners, Bosch’s global manufacturing, engineering, and sales network covers nearly every country in the world. With its more than 400 locations worldwide, the Bosch Group has been carbon neutral since the first quarter of 2020. The basis for the company’s future growth is its innovative strength. At 128 locations across the globe, Bosch employs some 76,100 associates in research and development, of which more than 38,000 are software engineers.

Additional information is available online at www.bosch.hu, iot.boschblog.hu, www.bosch.com, www.iot.bosch.com, www.bosch-press.com, www.twitter.com/BoschPresse