Plochingen, Germany – For vehicle workshops, the growing number of hybrid and electric vehicles on the roads is presenting new challenges. Work on electric and hybrid vehicles requires specialist expertise, and workshop technicians need specific training to be able to handle the high-voltage systems in electric vehicles. To support workshops that work on these alternative powertrains, Bosch’s Esitronic 2.0 Online diagnostic software now covers well over 200 electric and hybrid vehicle models. As these vehicles are now included in Bosch’s standard diagnostic software package, the workshop does not need to purchase a separate license to access extensive diagnostic data relating to electric and hybrid vehicles.

Safely disconnecting the high-voltage system

For many jobs on electric and hybrid vehicles, the priority is to isolate the high-voltage system, making it safe and to protect workshop technicians from potential electrocution. This involves disconnecting the high-voltage system from the vehicle and discharging any residual current. After disconnecting the system, technicians must always ensure that the vehicle cannot be switched on again, and they also need to check and document that no voltage is present. Once these steps have been completed, it is safe to work on or near high-voltage components. Depending on the manufacturer and vehicle model, however, the voltage disconnection process specified by the manufacturer and the corresponding instructions may vary. Compliance with the manufacturer’s specifications and correctly isolating the battery are particularly important for the safety of workshop technicians. In Esitronic 2.0 Online, therefore, Bosch provides detailed instructions for the vehicle-specific isolation process based on manufacturer specifications and data.

Reading out and documenting the state of the high-voltage battery

As it ages, the high-voltage battery of an electric or hybrid vehicle loses storage capacity. For this reason, some vehicle manufacturers provide diagnostic data on the condition of the high-voltage battery, called the ‘State of Health’ (SOH). With the 2023/3 software update, the new “HV battery (SOH)” tab is available in the navigation bar of the Esitronic diagnostic software. If the vehicle manufacturer provides corresponding data in the HV battery management system, the Esitronic user can use a special test function to read and print out the information. The state of health of the high-voltage battery is displayed as a percentage compared to a new battery. By printing out an SOH report generated by Esitronic, the workshop can provide vehicle owners with the specific values of the high-voltage battery installed in their vehicle.

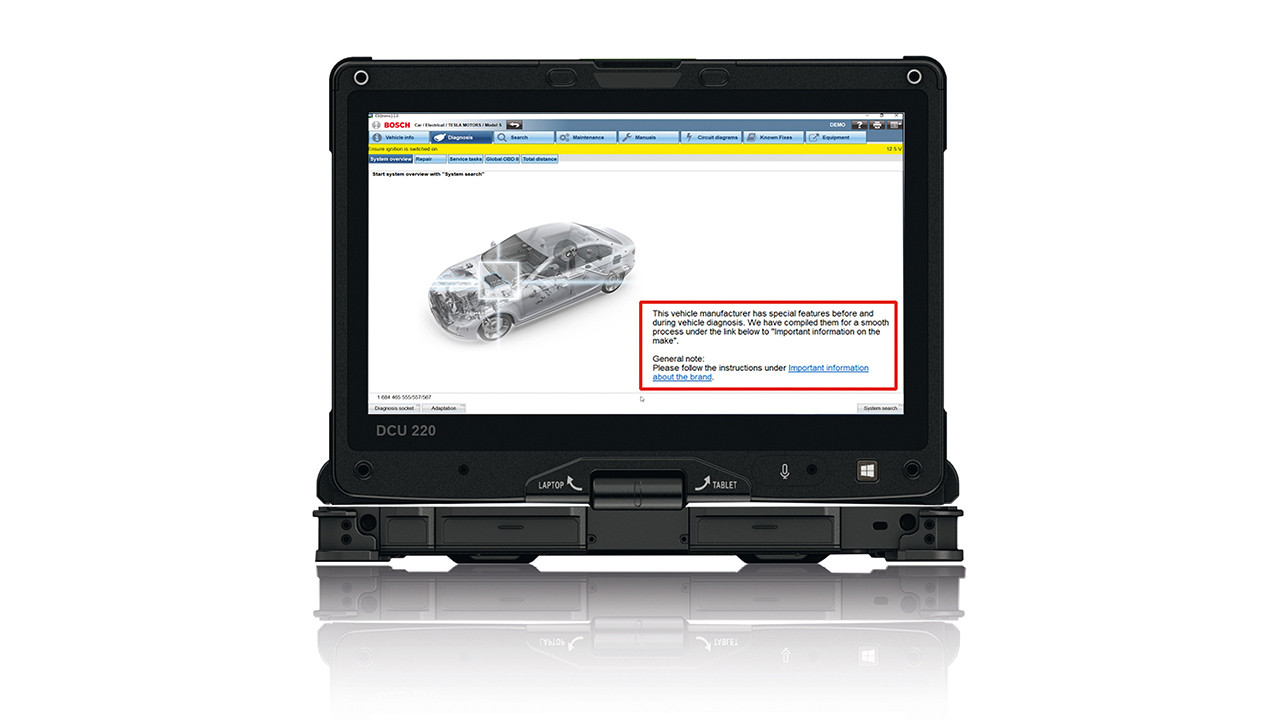

Anomalies in the diagnosis of Tesla models

Currently, Esitronic includes the Tesla Model S and Model X types. The U.S. manufacturer has brought many innovations to the field of diagnostics. As a consequence, it is important to be familiar with, and observe certain special features in order to run diagnostics successfully on Tesla vehicles. For example, on the Model S and X, the brake pedal must be depressed to put the vehicle into the mode that allows access to the CAN diagnostic functions. This enables the workshop to perform diagnostic work quickly and efficiently.

The “Important information about the brand” link in the Esitronic 2.0 Online diagnostic software explains these special features, giving the Esitronic user a quick overview of diagnostics on Tesla vehicles. Other Tesla models, as well as electric and hybrid models from other manufacturers, will be added to the Bosch diagnostic software as part of the regular updates offered.

Mónika Hack

+36 70 510 5516

The Automotive Aftermarket division (AA) provides the aftermarket and repair shops worldwide with modern diagnostic and repair shop equipment and a wide range of spare parts – from new and exchange parts to repair solutions – for passenger cars and commercial vehicles. Its product portfolio includes products made as Bosch original equipment, as well as aftermarket products and services developed and manufactured in-house. About 13,000 associates in more than 150 countries, as well as a global logistics network, ensure that spare parts reach customers quickly and on time. AA supplies testing and repair-shop technology, diagnostic software, service training, and information services. In addition, the division is responsible for the “Bosch Service” repair-shop franchise, world’s largest independent chains of repair-shops, with some 15,000 workshops, and more than 1,000 “AutoCrew” partners.

Additional information can be accessed at www.boschaftermarket.com

The Bosch Group is a leading global supplier of technology and services. It employs roughly 421,000 associates worldwide (as of December 31, 2022). The company generated sales of 88.2 billion euros in 2022. Its operations are divided into four business sectors: Mobility Solutions, Industrial Technology, Consumer Goods, and Energy and Building Technology. As a leading IoT provider, Bosch offers innovative solutions for smart homes, Industry 4.0, and connected mobility. Bosch is pursuing a vision of mobility that is sustainable, safe, and exciting. It uses its expertise in sensor technology, software, and services, as well as its own IoT cloud, to offer its customers connected, cross-domain solutions from a single source. The Bosch Group’s strategic objective is to facilitate connected living with products and solutions that either contain artificial intelligence (AI) or have been developed or manufactured with its help. Bosch improves quality of life worldwide with products and services that are innovative and spark enthusiasm. In short, Bosch creates technology that is “Invented for life.” The Bosch Group comprises Robert Bosch GmbH and its roughly 470 subsidiary and regional companies in over 60 countries. Including sales and service partners, Bosch’s global manufacturing, engineering, and sales network covers nearly every country in the world. With its more than 400 locations worldwide, the Bosch Group has been carbon neutral since the first quarter of 2020. The basis for the company’s future growth is its innovative strength. At 136 locations across the globe, Bosch employs some 85,500 associates in research and development, of which nearly 44,000 are software engineers.

Additional information is available online at www.bosch.hu, iot.boschblog.hu, www.bosch.com, www.iot.bosch.com, www.bosch-press.com, www.twitter.com/BoschPresse