Stuttgart, Germany – Fuel cells are finding their way onto the roads around the world. For Bosch, the next milestone in this development is a major order for electric air compressors with integrated power electronics. These compressors govern the fuel-cell system’s oxygen supply. Bosch has signed a long-term agreement with cellcentric to supply this high-tech component. A 50:50 joint venture between Daimler Truck AG and Volvo Group AB, cellcentric is responsible for all activities along the entire value chain. Like Bosch, the joint venture aims to become a leading global manufacturer of fuel-cell systems and thus to help make transportation climate neutral and sustainable by 2050. The air compressor will be part of the cellcentric fuel-cell system that will feature in heavy trucks and stationary applications in the future. Large-scale production is set to begin from around the middle of the decade.

Fuel cells make commercial vehicles climate neutral

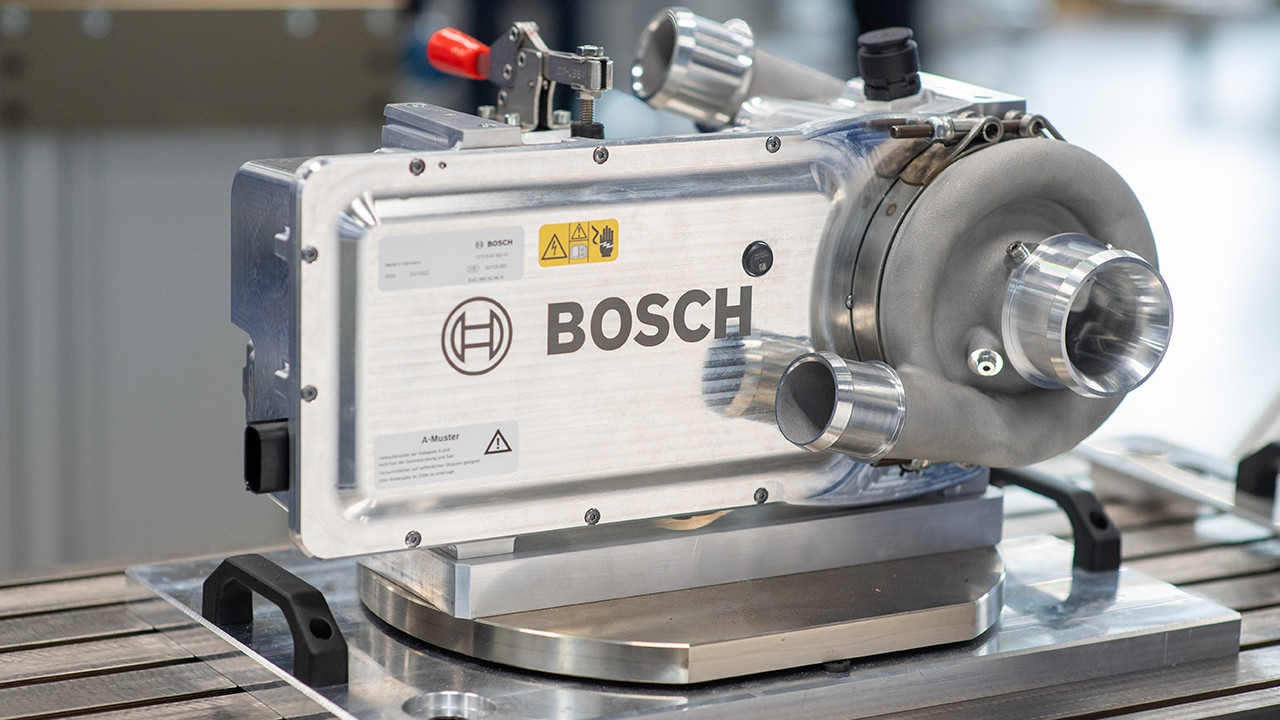

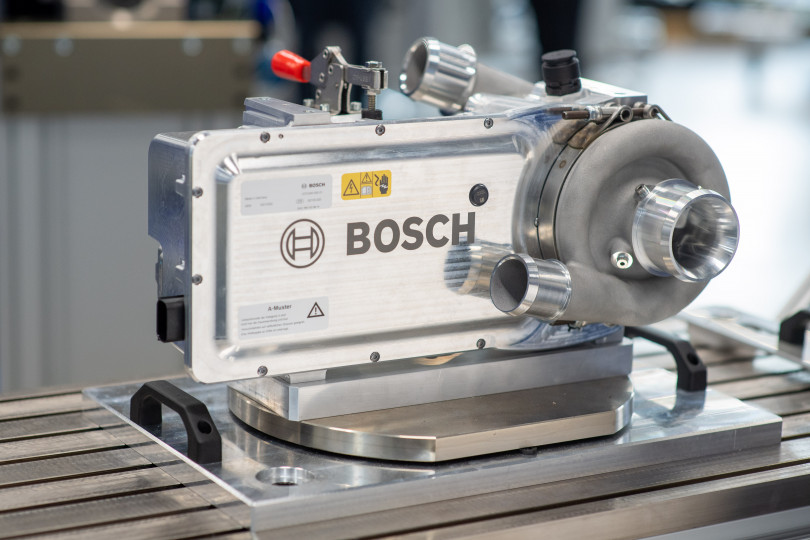

In fuel cells, hydrogen reacts with atmospheric oxygen to produce electrical energy as well as water and heat. Running a fuel-cell powertrain on hydrogen that is green – in other words, produced using renewable energy – makes the vehicle climate neutral. As the electric air compressor supplies the required amount of filtered air, it is one of the core components of a fuel-cell system. “Bosch is devoting a huge effort to developing this component. For example, we have 15 cross-divisional teams working to commercialize the electric air compressor,” says Dr. Uwe Gackstatter, president of the Bosch Powertrain Solutions division. Bosch offers the air compressor in two power classes – 20 and 30 kilowatts. The 30-kilowatt class is rated for voltages from 450 to 850 volts, while the 20-kilowatt class is rated for either 250–450 volts or 450–850 volts. The compressor wheel reaches speeds of more than 100,000 rpm. “The combination of a high-speed electric motor with integrated power electronics enables easy system integration at competitive manufacturing costs,” Gackstatter says. In addition, the silicon carbide semiconductors used in Bosch power electronics make this powerful component particularly efficient. It is features such as these that cellcentric was looking for.

High-tech product secures jobs

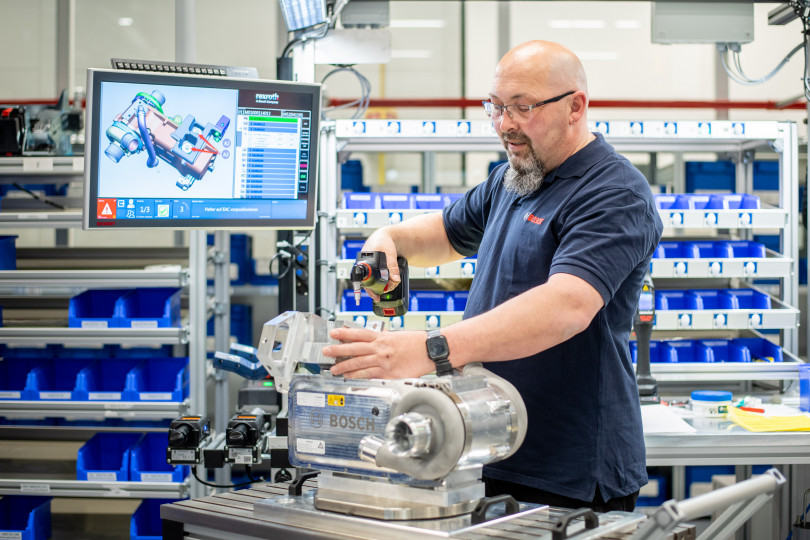

With the air compressor, the greatest technical challenge lies in scaling up the production of the high-speed electric motors with their air bearings and power electronics from customized to large-scale manufacturing. Since the overall technical complexity is comparable with that of a diesel injection system for commercial vehicles, the effect of these systems on employment is a positive one. “This promising component secures jobs at our Homburg plant,” Gackstatter says.

Bosch is working on mobile and stationary fuel cells

Bosch believes that hydrogen has a bright future as an energy carrier, and is making considerable upfront investments in this area. From 2021 to 2024, the company plans to invest around 600 million euros in mobile fuel-cell applications and a further 400 million euros in stationary ones for the generation of electricity and heat. The portfolio for vehicles ranges from individual sensors to core components such as the electric air compressor and the stack to the complete fuel-cell module.

Mónika Hack

+36 70 510 5516

Mobility Solutions is the largest Bosch Group business sector. It generated sales of 42.1 billion euros in 2020, and thus contributed 59 percent of total sales from operations. This makes the Bosch Group one of the leading automotive suppliers. The Mobility Solutions business sector pursues a vision of mobility that is safe, sustainable, and exciting, and combines the group’s expertise in the domains of personalization, automation, electrification, and connectivity. For its customers, the outcome is integrated mobility solutions. The business sector’s main areas of activity are injection technology and powertrain peripherals for internal-combustion engines, diverse solutions for powertrain electrification, vehicle safety systems, driver-assistance and automated functions, technology for user-friendly infotainment as well as vehicle-to-vehicle and vehicle-to-infrastructure communication, repair-shop concepts, and technology and services for the automotive aftermarket. Bosch is synonymous with important automotive innovations, such as electronic engine management, the ESP anti-skid system, and common-rail diesel technology.

The Bosch Group is a leading global supplier of technology and services. It employs roughly 395,000 associates worldwide (as of December 31, 2020). The company generated sales of 71.5 billion euros in 2020. Its operations are divided into four business sectors: Mobility Solutions, Industrial Technology, Consumer Goods, and Energy and Building Technology. As a leading IoT provider, Bosch offers innovative solutions for smart homes, Industry 4.0, and connected mobility. Bosch is pursuing a vision of mobility that is sustainable, safe, and exciting. It uses its expertise in sensor technology, software, and services, as well as its own IoT cloud, to offer its customers connected, cross-domain solutions from a single source. The Bosch Group’s strategic objective is to facilitate connected living with products and solutions that either contain artificial intelligence (AI) or have been developed or manufactured with its help. Bosch improves quality of life worldwide with products and services that are innovative and spark enthusiasm. In short, Bosch creates technology that is “Invented for life.” The Bosch Group comprises Robert Bosch GmbH and its roughly 440 subsidiary and regional companies in some 60 countries. Including sales and service partners, Bosch’s global manufacturing, engineering, and sales network covers nearly every country in the world. With its more than 400 locations worldwide, the Bosch Group has been carbon neutral since the first quarter of 2020. The basis for the company’s future growth is its innovative strength. At 129 locations across the globe, Bosch employs some 73,000 associates in research and development, of which nearly 34,000 are software engineers.

Additional information is available online at www.bosch.hu, iot.boschblog.hu, www.bosch.com, www.iot.bosch.com, www.bosch-press.com, http://www.twitter.com/BoschPress.